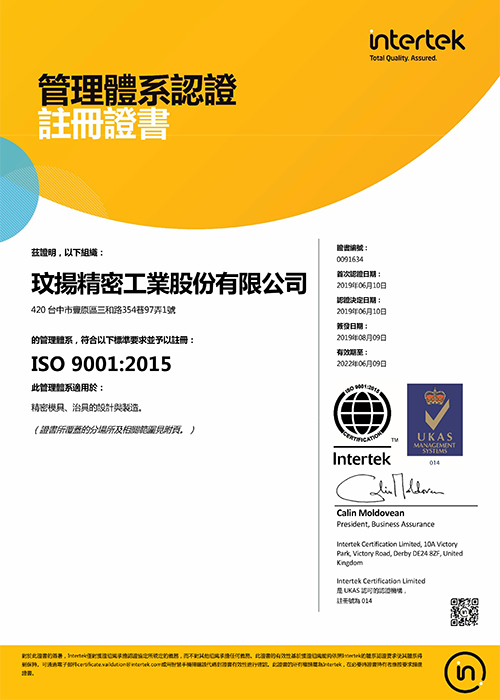

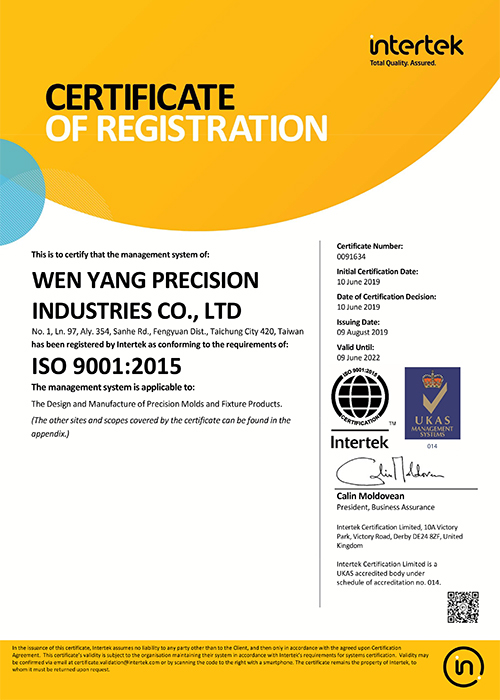

Wen Yang passed the ISO9001:2015 quality management system in June 2019. The inspection equipment is sophisticated and can be inspected in accordance with customers' inspection specifications.

Wen Yang was founded in 1998, from 5 employees to 62 employees today, from an annual turnover of 4.6 million to the current 68 million, from OEM to ODM. Along the way, we have been cautious and strictly adhered to the field of semiconductor precision mold processing. We have continued to cultivate and research. Especially in the grinding and polishing technology, we are leading the domestic industry, even not losing to Germany and Japan. Wen Yang has professional and exquisite manufacturing technology and quality, has a variety of measurement and inspection equipment. It also has high-precision milling, grinding, polishing, surface treatment equipment that can manufacture a high-tech electronics industry precision molds, semiconductor molds, jig development and actively become A leading manufacturer in the processing industry, marketing the world, and designing customized products for customers, such as the development of silicon carbide, aluminum nitride micro-sculpting molding technology, the design and development of three-stage chip ejector, and the development and research of improved jig group of BO chip.

Wen Yang has been affirmed by many major manufacturers. In 2012, Lingsen Precision Industry Co., Ltd. awarded the Supplier Gold Award. In 2013,it was also awarded the Excellent Supplier Award by Siliconware Precision Industry Co., Ltd. Appraised as the best third-party vendor. It was also selected by the Ministry of Economic Affairs as an excellent business person for issuing uniform invoices. It passed the ISO9001:2015 quality control system on June 10, 2019. Wen Yang adheres to the principle of quality first, customer first, profit creation, sustainable operation, and continuous improvement of precision processing, grinding and polishing technology, becoming the best partner of Taiwan's semiconductor factory [mold, jig] for local production.

Wen Yang has an excellent design team and strong ability in prototype development. It can provide manufacturing products according to customer needs, such as various mechanical equipment parts, office supplies, molds, fixtures, special polishing, development and manufacturing, etc. , The product can be produced separately or in mass production. It can be inspected in accordance with the inspection method required by the customer, and provide relevant inspection data and material related certification documents. We have fast delivery, preferential unit price, honest and responsible, quality assurance, and service-oriented. This is where other manufacturers' mass production is not as good as ours.

"Fast delivery, preferential unit price, responsible integrity, quality assurance, service first"

Continuously improve precision processing, grinding and polishing technology, becoming the best partner for local production of Taiwan’s semiconductor factory [ molds, fixtures ]

"Quality First", "Customer First", "Profit Creation", "Sustainable Management"

Wen Yang passed the ISO9001:2015 quality management system in June 2019. The inspection equipment is sophisticated and can be inspected in accordance with customers' inspection specifications.